Dual fuel is simultaneous burning of two energizes ie. Methane based fuel and Diesel are consumed in concurrence to run the motor. In double fuel mode, the motor can work either on a combination of diesel and methane fills or on 100 percent diesel fuel. In no conditions, the motor can work on vaporous powers solely. This arrangement is accessible for vehicles as well as fixed motors. Dual Fuel Solutions is a selected speaker agent from Ideal Deals Arrangements Ltd, trading as Ideal4Finance.

The best deal maker is a credit agent and not a loan specialist. Funding is based on rank. The rate offered is temporary, and it will depend on your personal situation. The rate of progress and the length of time. During dual-fuel operation, a small amount of diesel fuel serves as the ignition source for the air-gas mixture. A rich mixture of methane gas replaces a large part of the diesel fuel to produce the corresponding calorific energy during combustion in the cylinder. The things that come out of such engines see a maintenance process. In the current market conditions this also means cost reduction.

Dual Fuel technology

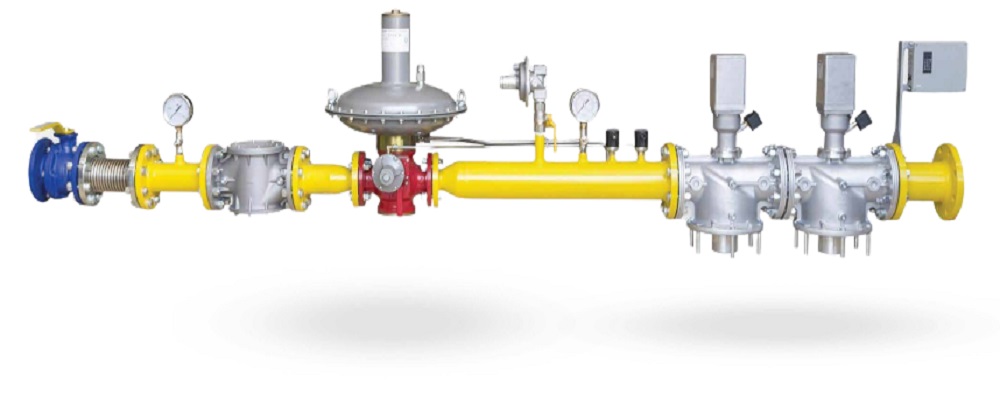

Dual fuel technology is a process that allows diesel engines to reduce their use of diesel fuel and replace it with other fuels in certain areas. Other common types of fuel include LPG (autogas), CNG, LNG, biomethane, ethanol, methanol and hydrogen. Alternative fuels do not completely replace diesel, but the two fuels work together to provide an efficient combustion process. A dual fuel engine (Diesel-CNG) is a basic diesel engine equipped with a dual fuel conversion kit to allow the use of other clean burning fuels such as natural gas. In this engine, diesel and gas are burned simultaneously.

Air is introduced into the cylinder and intake air; the diesel fuel injection rate is thus reduced.

Dual fuel engines have many advantages such as fuel flexibility, higher compression ratios, better performance and few changes to existing diesel engines. It is an environmentally friendly technology due to the reduction of PM. And smoke emissions while maintaining the efficiency of diesel combustion.

Dual Fuel Combustion

Dual fuel combustion, high-octane, high-burning fuel (e.g., gasoline, gas) is introduced early by injecting the fuel into the feed port and the smaller fuel burners. (e.g. diesel fuel) is injected directly into the vicinity. combustion chamber. TDC to be the ignition source [99, 100]. A dual-fuel mixture can achieve better ratings than PPCI at high loads, because the higher octane ratio of the fuel boosts it better before ignition.

However, two fuel conditions still encounter some problems due to the special structure of combustion. If the fuel used to fuel the premix is not properly formulated. The fuel itself will be the source of the soot. This occurs easily in the early injection system, where the evaporation and mixing time of the direct injection oil is short. Another issue is that a high octane lean premix will cause HC emissions to be less flammable. And sometimes lead to greater emissions, especially at low loads [101]. With the expansion of PODE into the immediate infusion fuel, the start and the fire spread nature of the super charged combination can be improved. And the residue development in the fuel-rich locales will be restrained because of the great cetane number and oxygen content of PODE.

Dual Fuel Engine

The Stone Age did not end because the earth ran out of stone, the oil age will not end because we ran out of oil. Instead, the oil age will end as we (communities, businesses and governments) make the energy transition towards our final destination: 100% renewable energy. In this energy transition journey, there are big steps we all celebrate. Such as the increase in green hydrogen and electric trains. There are also incremental processes – those that move in the right direction, those that challenge the status quo, and those that bring us closer to our ultimate goal.

The use of dual fuel systems is one of these increasing trends. It is the right step immediately for the oil and gas industry to reduce its environmental footprint and improve its financial performance. The company uses technologies ranging from microgrids to low-cost wind turbines in this journey. And the dual-fuel engine is the right addition to this portfolio. Dual-fuel engine technology has proven itself over the years in well drilling and utility applications. Given the increasing interest in dual oil solutions, this article explains what dual oil machines are and their benefits in oil and gas applications.

Dual Fuel Generator

Dual fuel generators get power from two different types of fuel and use them simultaneously. They are often confused with their cousin, the dual fuel producer. Which uses two types of fuel and relies on them together. Dual fuel generators work with propane and gas. And because they are able to use two different types of fuel at different times. They tend to be heavier and more expensive. ability to convert more than one fuel.

Choosing a dual fuel truck comes down to what you want the truck for in the first place. As a backup system for your home or to provide electricity while camping, a dual fuel generator is a great choice. This type of generator has a backup when one of the other sources of power fails or is unavailable. Compared to solar generators, dual fuel generators have many plants. But they can transmit energy for a longer period of time than solar models. When fitted with diesel or mono fuel, you will get more confidence from its dual power system.

Conclusion

Dual fuel engines always use some fuel to start the fire fighting process. A dedicated dual fuel engine can use less than 1% of fuel and switch directly from fuel to gas. And vice versa under load conditions. Care should always be taken to ensure that two oil engines are properly maintained with the characteristics of the oil concerned. Wobbe index, methane index, cetane number and carbon aromaticity index are important qualifications in this regard. One plant based on many bi-fuel bikes in the same way offers great flexibility. Both in terms of fuel consumption and performance. This enhances the reliability of the power supply.