Imagine a system that can change, handle pressure, and get rid of shaking, all while helping the

environment. Welcome to the world of Rubber Expansion Bellows and stainless steel flexible

hose pipe.

Ever wondered how these unassuming components play a pivotal role in industries ranging from

power generation to petrochemicals?

Whether you are a student who loves learning, an experienced engineer, or just someone

interested in technology. This article will take you on a tour of the exciting world of engineering

advancements. Get ready to see how these parts are changing flexibility and reliability.

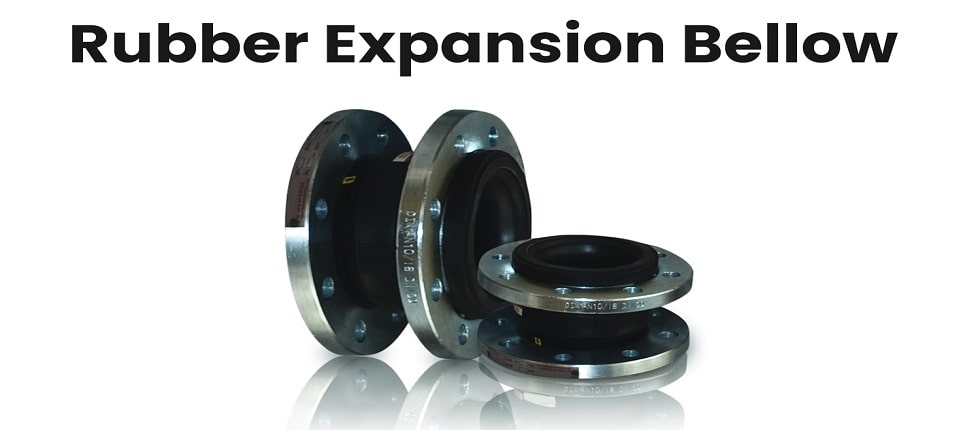

Understanding Rubber Expansion Bellows:

Rubber expansion bellows, or expansion joints, are flexible links used to soak up heat

expansion, vibrations, and movement in piping and duct systems. These bellows are made to

help reduce stress and protect equipment and buildings from getting damaged. They do this by

allowing for movement caused by changes in temperature and other forces. Rubber expansion

bellows are great because they can stop vibrations, noise, and shock. This helps systems last

longer and saves money on maintenance.

Easyflex’s rubber expansion bellows are known for their high quality and excellent performance.

These expansion bellows are made from very good rubber materials. They are very stretchy

and can absorb movements well without getting damaged easily. The bellows are designed to

handle different temperatures and not get damaged, so they can be used in many industries like

heating and air conditioning, chemicals, making power, and others.

Advantages of Rubber Expansion Bellows:

Flexibility and Movement Absorption: Rubber expansion bellow is very good at absorbing

movements in different directions, like up and down, side to side, and turning. This helps protect

the pipes from getting damaged because of stress.

Vibration Isolation: The natural ability of rubber to absorb vibrations helps to decrease the

transfer of vibrations, making it more comfortable for people who work near machines.

Noise Reduction: By reducing movement and absorbing sound, these bellows help make the

work area quieter.

Corrosion Resistance: Rubber expansion bellows are made to withstand damage caused by

chemicals. This helps them last longer when used in tough industrial settings.

Installation Versatility: These expansion bellows come in different options to fit different pipe

designs and limited spaces.

SS Flexible Hose Pipe: A Marvel of Flexibility and Strength

Stainless Steel (SS) Flexible hose pipes made from durable and high-quality stainless steel are

another important invention that has greatly improved the way we transport and manage fluids.

These hoses are made from a mix of stainless-steel wires and tubes. Which makes them very

flexible but still strong. SS Flexible Hose Pipe is used in many different industries because they

can handle high pressures, corrosive materials, and very hot or cold temperatures.

Easyflex makes flexible hose pipes that are better than what’s expected in the industry. These

hoses are made from high-quality stainless steel. So they won’t get rusty, damaged, or dirty

easily. Additionally, their adaptable design makes installation easier, saving time and money.

Key Benefits of Easyflex’s SS Flexible Hose Pipe:

Pressure Resistance: These hoses are able to handle strong pressure, which means they can

be used to move liquids in tough situations.

Temperature Stability: SS flexible hose can handle very hot or very cold environments without

getting damaged or losing their effectiveness.

Chemical Compatibility: The stainless steel used in this construction is able to work well with

many different chemicals, preventing any damage or breakdown of materials.

Longevity: Corrosion and wear resistant properties ensure that they will last a long time,

reducing the need for frequent replacements.

Versatility: These hoses come in different sizes and can be custom made for many different

uses in industry.

Energy Efficiency and Sustainability:

As industries work on using less energy and being more eco-friendly, they are creating rubber

expansion bellows and SS flexible hose pipes that are designed to be more efficient.

Innovations focus on making designs better to lower the amount of resistance and disruption in

fluid flow, so less energy is needed to move the fluid. Moreover, more people are starting to use

environmentally friendly materials and processes in manufacturing, which means these

components are in line with goals for sustainability.

Hybrid Solutions for Complex Challenges:

In complicated engineering situations, more and more often we are using hybrid solutions that

combine the benefits of rubber expansion bellows and SS flexible hose pipes. For example,

adding bellows to flexible hose pipes can make them more flexible and able to absorb

movement. This can still keep them strong because they are made of stainless steel. These

mixed solutions help to solve many different problems in industries like aerospace, defense, and

marine engineering.

Conclusion-

As rules about being safe and taking care of the environment get stricter. New ideas are focused

on making sure everyone follows them. We are creating rubber expansion bellows and stainless

steel flexible hose pipes that go above and beyond industry standards. Our main focus is

keeping everyone safe and lowering the chance of any possible dangers. These advancements

not only make things work better but also give peace of mind to industries that have to follow

strict rules. Industries want to improve how well they work, be more environmentally friendly, and keep

people safe. Rubber expansion bellows and SS flexible hose pipes are new inventions that can

help with these goals. They are very important for solving these challenges. By keeping up with

these trends, engineers and professionals can use the newest advancements to make systems

that are not only very good but also ready for the future.