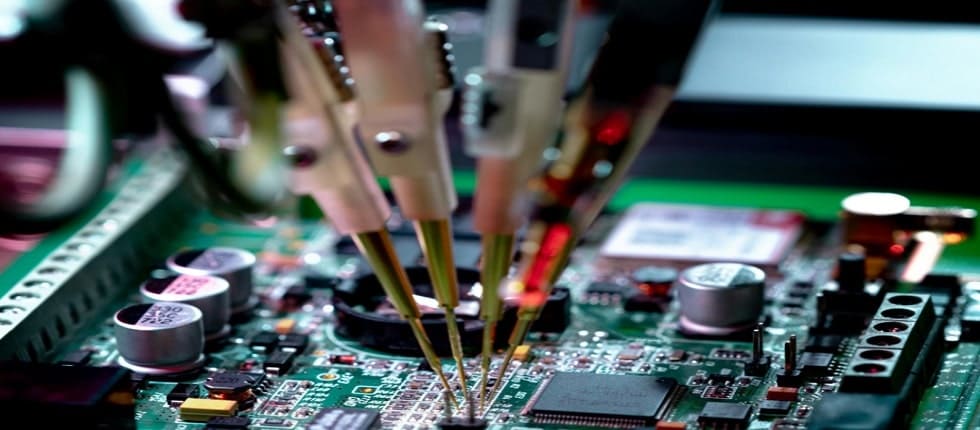

In the rapidly evolving world of electronics production, accuracy and efficiency are critical. Turnkey PCB assembly has emerged as a comprehensive solution to simplify and streamline the production process. It offers numerous advantages that cater to businesses seeking reliable and time-efficient assembly services.

Understanding the PCB Assembly Process

The PCB assembly process involves several stages, starting from schematic design to the final assembly and testing of the printed circuit board. Each step is crucial in ensuring a flawless end product.

● Schematic Design

The process begins with designing the PCB schematic, which serves as the blueprint for the board’s layout and connections between components. Designers use specialized software to create the schematic, and it is essential to have a well-defined design to avoid issues during manufacturing.

● Component Sourcing

Once the schematic is ready, the next step is sourcing the components. These services have established partnerships with trusted suppliers, simplifying the procurement process and ensuring the availability of high-quality components.

● PCB Fabrication

With components in hand, the PCB fabrication process starts. The design data is used to create the actual board, which serves as the foundation for mounting the components.

● Assembly and Testing

During assembly, automated machines precisely place the components on the board. After assembly, rigorous testing procedures are conducted to identify and rectify any potential defects, ensuring the final product meets quality standards.

Advantages of Turnkey PCB Assembly

● Time and Cost Efficiency

Turnkey PCB assembly significantly reduces the time and effort required to manage multiple tasks. Businesses can focus on their core competencies while leaving the intricate assembly process to the experts.

● Reduced Hassle and Streamlined Process

By opting for a turnkey solution, businesses avoid the need to coordinate with multiple vendors for different assembly components. This streamlines the process, reduces communication challenges, and minimizes the risk of errors.

● Quality Assurance

Experienced turnkey PCB assembly providers implement stringent quality control measures at every stage. This commitment to quality ensures that the final products meet industry standards and customer expectations.

● Expertise and Support

With experienced professionals handling the assembly, businesses benefit from technical expertise and ongoing support, right from design to the final product. This support is invaluable in addressing any issues that may arise during the process.

Choosing the Right Turnkey PCB Assembly Service

Selecting the appropriate turnkey PCB assembly service provider is essential to ensure a successful and hassle-free experience.

● Experience and Reputation

Research the company’s track record and reputation within the industry. A proven track record reflects the provider’s ability to deliver high-quality services consistently.

● Manufacturing Capabilities

Evaluate the provider’s manufacturing capabilities, including the types of components they can handle, production capacity, and their ability to accommodate custom requirements.

● Quality Control Measures

Inquire about the quality control processes implemented during assembly and testing. A reliable provider will have robust measures in place to ensure defect-free products.

● Customer Support

Prompt and effective customer support is vital in addressing any concerns and providing timely assistance.

Industries and Applications Benefiting from Turnkey PCB Assembly

It is widely utilized across various industries and applications due to its numerous advantages. Some of the prominent sectors that benefit from this service include:

● Electronics

In the rapidly evolving electronics industry, it expedites product development and enhances time-to-market for cutting-edge electronic devices.

● Automotive

Automotive manufacturers rely on turnkey assembly services to meet the demand for sophisticated electronic components used in modern vehicles.

● Medical Devices

The medical industry requires precision and quality in every aspect. It ensures that medical devices meet the highest standards of performance and safety.

● Aerospace and Defense

The aerospace and defense sectors demand robust and reliable electronics. Turnkey assembly guarantees the delivery of high-quality PCBs for critical applications.

● Consumer Goods

From smart gadgets to household appliances, it aids in producing innovative and reliable consumer goods.

Common FAQs about Turnkey PCB Assembly

1. What is Turnkey PCB Assembly?

It is a comprehensive service that handles the entire PCB manufacturing process, from design to assembly and testing.

2. How long does the assembly process take?

The assembly process duration varies based on factors such as the complexity of the design and the provider’s production capacity. It takes a few days to several weeks.

3. Is Turnkey PCB Assembly suitable for small-scale production?

Yes, it is well-suited for both small-scale and large-scale production runs.

4. What are the costs involved in Turnkey PCB Assembly?

The costs depend on factors like the complexity of the design, the number of components, and the volume of production. Providers offer transparent pricing models.

5. How to ensure the quality of the assembled PCBs?

Choose a reputable turnkey PCB assembly service provider with a proven track record of delivering high-quality products. Ask about their quality control procedures as well.

Also Read: High Volume PCB Assembly

Conclusion

It is an invaluable solution for businesses seeking efficient and reliable PCB manufacturing. By streamlining the process, reducing costs, and ensuring quality, this service enables businesses to focus on innovation and growth. Embracing turnkey PCB assembly is a strategic move that leads to a competitive edge in the dynamic world of electronics.

FAQs

- Can turnkey PCB assembly cater to specialized design requirements?

Yes, its services can accommodate customized design requirements to meet specific project needs.

- Are there any geographical limitations for availing of turnkey PCB assembly services?

No, its services are accessible globally, and providers often offer international shipping options.

- How can I ensure the confidentiality of my design files during the assembly process?

Reputable turnkey assembly providers prioritize data security and confidentiality, employing secure protocols and non-disclosure agreements.

- Can turnkey PCB assembly handle high-volume production?

Yes, turnkey assembly services are equipped to handle high-volume production, making them suitable for both prototyping and large-scale manufacturing.

- What is the typical warranty period offered by turnkey PCB assembly providers?

Warranty periods may vary among providers but usually range from